AQ5Z

安全钳安装使用说明书

Operation Manual for Installation of

AQ5Z Safety Gear

石家庄通安机械有限公司

Shijiazhuang Tong’an Machinery Co., Ltd

地址:河北省石家庄市藁城区廉州镇陈家庄三排村东800米处(职教中心北侧)

Add: 800 Meters East of Sanpai Village, Chenjia Zhuang, Lianzhou Township ,Gaocheng District,

Shijiazhuang, Hebei, China

电话(Tel):++86-0311-88162296

传真(Fax):++86-0311-88169915

邮编(Zip Code):052160

网址(Website):www.tonganjixie.com

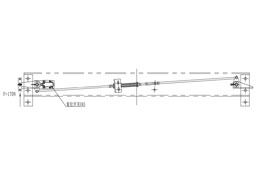

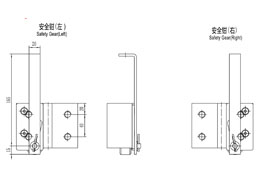

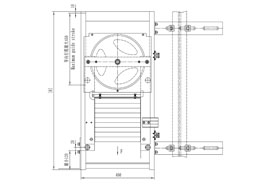

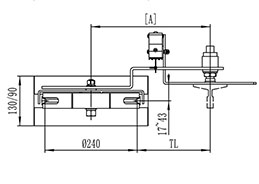

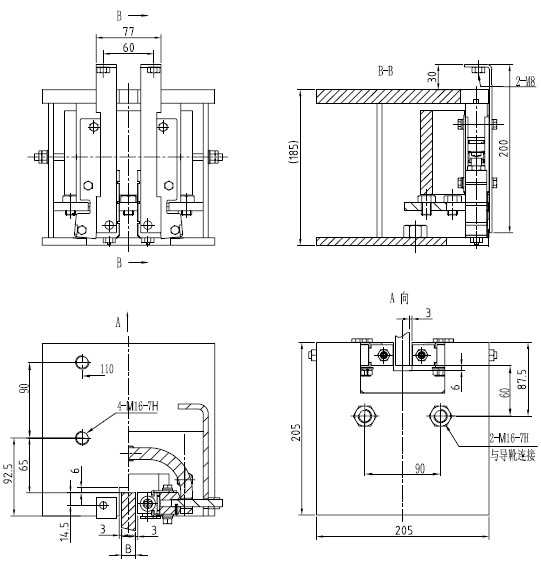

注:若P+Q为4500-5000kg,则高度(185)改为(195)。

Note: If P+Q is 4500-5000kg, the height (185 )to (195)。

S3:0101010317

Ⅰ Usage and Characteristic

Safety gear is an important safety element of elevator ,and its main application is

controlled by the speed governor to stop the car and its load on the guide rail to avoid the

occurrence of accidents ,when the elevator car over-speeds in down direction under the

situation of breakdown ,and its speed reaches the governor tripping speed.

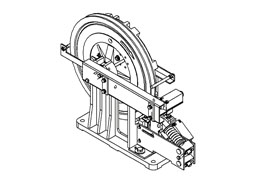

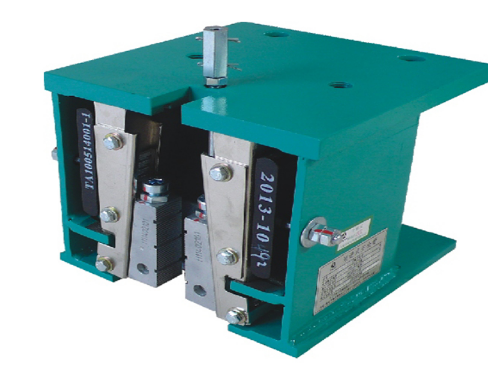

AQ5Z safety gear ,With U-shape spring as elastic element, this type of safety gear is

progressive, and has characteristics, such as stable braking, reliable braking ability. It is mainly used for medium and low speed lift whose rated speed is lower than or equal to 2.5m/s;

Ⅱ Main Technical Parameters

1.Rated speed:V=0.25~2.5 m/s

2.Allowed total quality:P+Q: from 1200 to 5000Kg

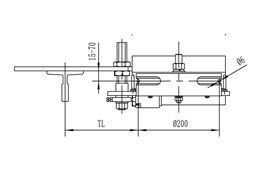

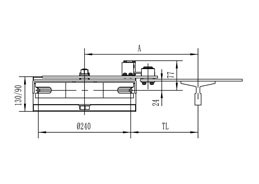

3.Width of guide rail:9,10, 15.88, 16 mm

Guide rail processing method: machinery processing. the guides our safety gear used

has the same performance and parameters with that of National Elevator Inspaction

and testing center used.

Ⅲ Direction for Use

1.Use this product strictly according to the technical parameter on the nameplate.

2.The product has been checked entirely and sealed before leaving the factory. Users

should not remove the seal and adjust by themselves.

3.The safety gear should be installed on the connecting pieces of two ends of the

Ⅰ用途及特点

安全钳是电梯的重要安全部件,它的主要作用是当电梯轿厢在故障状态下超速下行,速度达到限速器的动作速度时,由限速器操纵安全钳把轿厢及其载荷制停在导轨上,防止意外事故的发生。

AQ5Z安全钳是以U形弹簧为弹性元件的渐进式安全钳,其制动平稳,制动性能可靠,主要用于额定速度小于等于2.5m/s的中低速电梯;

Ⅱ主要技术参数

1.额定速度:V=0.25~2.5 m/s

2.总容许质量:P+Q=1200~5000 kg

3.导轨宽度:9,10,15.88, 16 mm

导轨采用机械加工制作。本安全钳所使用的导轨的性能及参数与国家电梯质量监督检

验中心所使用的导轨的性能及参数相同。

Ⅲ使用说明

1.应严格按照本产品铭牌上的技术参数使用本产品。

2.产品出厂前已调试完毕,并加以漆封,安装使用者不得随意拆封调整。

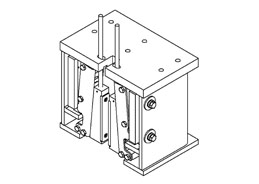

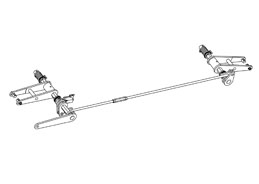

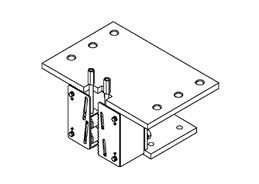

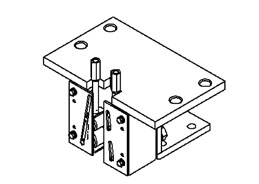

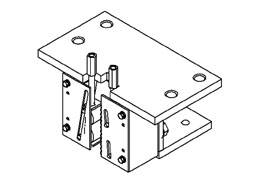

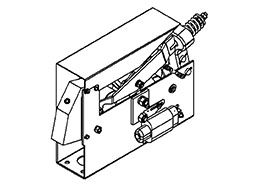

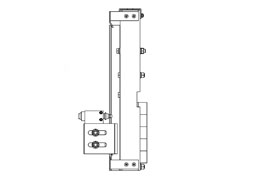

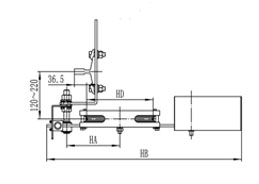

3.本安全钳应安装在轿厢下横梁两端的连接件上。其安装连接尺寸如附图所示。

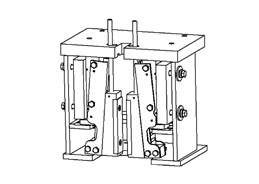

4.安装顺序

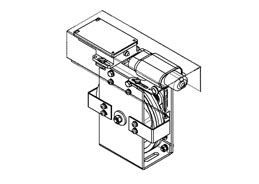

(1) 用螺栓将安全钳连接在轿厢下横梁的两端。

(2) 按图示调整安全钳的位置,使安全钳两侧滑块齿面与导轨之间的间隙一致均为

beam under the cage of lift. Please see the attached sketch for the installation and

connection dimensions.

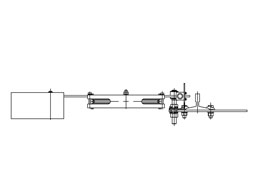

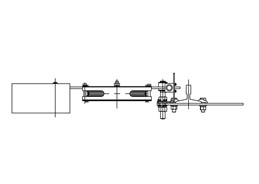

4.Installation Sequence

a)Connect safety gear to the two ends of the beam under the cage of lift.

b)Adjust the position of safety gear to make the gaps between the two sides sliding block of safety gear and lead rail be 3mm. And then tighten the bolts and nuts.

c) Screw the hoisting lever on the sliding wedge of the safety gear or on the hoisting board ,make the pull lever enter into enough ,and simultaneously make the sliding wedge hoist by 0.5mm and screw the bolt tightly to avoid loosening ,which can make sure the synchronization action of the two safety gears.

Ⅳ Performance Checking

Use a tiny force to hoist the pull lever to make the two wedges touch the guide

rail ,and keep no retardance during the hoisting .When reaching to the working

position ,the wedge should clamp the guide rail slimly ,then release the wedges to the

non-working position.

Ⅴ Maintenance

3mm,旋紧螺栓、螺母。

(3) 将提拉杆螺栓旋到安全钳滑动楔块上或提拉板上,拉杆旋入足够的深度,并使

滑动楔块同时提升0.5mm后用螺母拼紧以防松动,保证两安全钳同步动作。

Ⅳ性能检查

用微小力提起拉杆,使两楔块同时接触导轨,在提升时不应有阻滞现象,到达工作位置时,楔块对导轨应有微夹紧现象,然后将楔块放回到非工作位置。

Ⅴ维护保养

1)功能检查:每年至少检查一次安全钳的功能是否完好。

2)使用过程中安全钳每动作一次后都应进行一次全面的检查与调整。

3)每年至少应对轨隙检查两次,而在制动后必须进行轨隙检查。

4)滑动楔块磨损过大应予以更换。

1)Inspection of function :Every year check once at least whether its function is

under good condition.

2)It is necessary to check and adjust the safety gear completely after its every

operation

3)Every year check the rail gap twice at least .After brake ,it’s necessary to

check rail gap .

4)Movable wedge shall be replaced due to excessive abrasion .